Parker

Showing 163–171 of 178 results

-

Sale!

Subsea Needle Valve

Original price was: £1,000.00.£800.00Current price is: £800.00.Parker’s non-rising, non-rotating stem needle valve designed specifically to deliver smooth, low-torque performance in subsea applications. Featuring metal-to-metal seat for bubble-tight shut-off, longer stem/seat life, greater durability for repeated on/off cycles and reinforced PTFE/PEEK chevron packing below stem threads for dependable stem and body sealing. This subsea needle valve incorporates additional o-ring seals, which prevent the ingress of sea water into the valve which could adversely affect the operation of the valve as well as contaminate the process fluid.

The uni-directional valves are available in a range of corrosion-resistant alloys and are suitable for equipment located at depths down to 3,050m.

The valves are designed to facilitate operation either manually or by a Remotely Operated Vehicle (ROV).

Parker’s subsea needle valves have been designed to meet or exceed the rigorous qualification test requirements of API 17D PSL 3/3G. The design’s structural integrity and performance have been confirmed by Lloyds inspectors witnessing the API 17D valve design validation protocol. This was carried out on the base 316SS model and included the API 6A PR2F PSL3/3G uni-directional testing protocol as well as the API 17D Hyperbaric test protocol.

-

Sale!

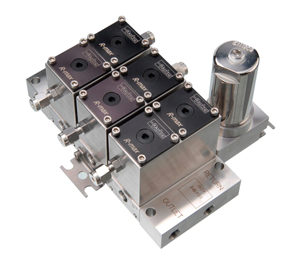

Surface Mount/ Stream Switching

Original price was: £1,000.00.£800.00Current price is: £800.00.- Surface mount technology for stream switching valves

- Low internal volume to reduce system purge time

- Low pressure actuation of valves-40 psig (-2.76)

- Rated from vacuum to 500 psig (34 barg)

-

Sale!

SWB Series

Original price was: £1,000.00.£800.00Current price is: £800.00.- Zero clearance body allows repairs in field

- Spring loaded seats and stem seals

- Fully enclosed body bolts

- ISO-type actuator mounting design

- Available up to 1” full flow design

-

Sale!

Tube Bender

Original price was: £1,000.00.£800.00Current price is: £800.00.- High quality bending performance on stainless steel, and other hard tubing such as steel and titanium.

- Two stage design allows for in-place bending from 90° to 180° without ever crossing handles. Lock/unlock with a half turn rotation of the bending handle.

- Extra-long 16” (40 cm) handles increase leverage and roll dies in the bending form reduce force needed.

- Vice clamp built into bending form for extra stability

-

Sale!

Tube Clamps

Original price was: £1,000.00.£800.00Current price is: £800.00.- Suitable for general hydraulic applications.

- The function of tube clamps is the fixing of straight tubes, bent tubes and hoses, the broad product range of Parker tube clamps helps to find a solution for all requests and therefore extends the range of applications.

- Their notable features are re-set capability, high tensile strength, very high abrasion resistance and excellent resistance to cold.

- This range of features enlarges the number of possible applications and stretches the life-cycle of tube clamps.

-

Sale!

Tube Cutters

Original price was: £1,000.00.£800.00Current price is: £800.00.- Adjustable tube cutters are designed to produce square cut ends with no external burr and minimum internal burr when used on fully annealed copper, brass, aluminium and steel tube.

- Features a hardened and burnished tool-steel cutting wheel and a flare cut-off groove in roller.

- The handle feeds and adjusts the cutting wheel to uniformly cut tube as the cutter is rotated.

-

Sale!

U Series

Original price was: £1,000.00.£800.00Current price is: £800.00.- Stem packing below the threads isolates the thread lubricant from the flowRoddable, straight through flow path

- Severe service applications

- Panel mountable

- Ideal for steam blowdown

-

Sale!

Ultra High Pressure

Original price was: £1,000.00.£800.00Current price is: £800.00.Parker Autoclave Engineers High & Ultra High Pressure connections are a refinement of the original cone & thread joint which has been the standard connection in high pressure technology since its development by an agency of the US Government over 75 years ago. This design set precedence of quality and reliability found in all Parker Autoclave Engineers products to this day.

The pressure handling capabilities of this connection design have been applied successfully to control pressures up to 150,000 psi. All-metal sealing and working temperatures from 0° to 600°F (-18° to 315°C), along with a variety of different material options make this connection one of the most versatile ever. Fittings and tubing found in this section are designed using ASME B31.3 Chapter IX standards to be compatible with all of our Ultra High Pressure Valve and Fitting configurations.

-

Sale!

Ultra High Pressure Tubing

Original price was: £1,000.00.£800.00Current price is: £800.00.Parker Autoclave Engineers offers a selection of austenitic cold drawn stainless steel tubing designed to match the performance standards of Parker Autoclave valves and fittings. Parker Autoclave ultra high pressure tubing is manufactured of 316/316L (UNS S31600/S31603) or HP160 (100Ksi only) specifically for high pressure applications requiring both strength and corrosion resistance. The tubing is furnished in random lengths between 20 feet (6 meters) and 26.5 feet (8.0 meters). The average is 24 feet (7.3 meters). Our HP160 tubing was designed by Parker Autoclave Engineers specifically for High Cyclic use such as Waterjet cutting machines.

Manufactures Information